Preventing Over-Travel and Two-Blocking Incidents

How crane limit switches halt hoist motion before rope slack loss

Limit switches on cranes stop major accidents from happening by cutting off power at set points along the way. The switches keep track of where the hoist is going using either mechanical arms or encoder systems, and kick in when the hook gets too close to the top or reaches the ends of the trolley tracks. When these switches shut down the electricity before all the slack disappears from the ropes, they stop what's called two-blocking. This happens when hook blocks crash into the tip of the boom, which often leads to whole structures coming down. Good calibration creates this extra safety space between components, keeping the ropes tight enough while allowing for smoother slowdowns. According to industry reports, facilities that maintain their limit switches properly see about a 60-65% drop in lifting accidents compared to places where maintenance isn't done right.

Real-world failure analysis: Midwest steel plant OSHA report (2022)

In 2022, OSHA looked into what happened at a steel plant in the Midwest after workers noticed something was seriously wrong with their safety systems. The problem started when a crane's upper limit switch stopped working properly during the transport of molten metal ladles. What followed was pretty catastrophic - the crane kept going up past its safe limits, which caused a dangerous condition called two-blocking. This ultimately led to the hoist ropes snapping. An 18 ton load fell about 12 meters straight down, wrecking equipment worth around $740,000 according to Ponemon's report from last year. Looking deeper into the situation, investigators discovered that the plant had skipped installing the backup protection system specified in ASME B30.16 standards. If they'd had that second layer of defense, specifically a redundant limit switch, it might have kicked in and stopped everything before disaster struck. This whole mess explains why today's safety regulations push so hard for magnetic proximity switches instead of traditional mechanical ones. These newer switches actually work even when parts get stuck or jammed, which makes all the difference in preventing accidents like this one.

Understanding Operational vs. Safety-Critical Limit Switch Functions

There are different types of crane limit switches, each serving specific roles depending on how they're designed and where they get installed. The operational kind handles everyday tasks like stopping hoists when materials reach certain points during lifting operations. These switches focus on getting things done efficiently and consistently. When these fail, it usually just slows down work rather than causing major problems. Safety switches tell another story though. These bad boys stop disasters from happening, preventing dangerous situations such as two-blocking accidents or structural failures. They come equipped with backup systems, meet strict safety standards like SIL-2/PLd certification requirements, and are built so that when activated, nothing else matters except stopping whatever operation is underway. According to recent industry data from Lifting Equipment Digest in 2023, about one third of all crane incidents happen because people rely too much on regular operational switches instead of proper safety mechanisms for protection against hazards.

| Comparison Factor | Operational Switches | Safety-Critical Switches |

|---|---|---|

| Primary Objective | Process optimization | Hazard prevention |

| Failure Impact | Operational downtime | Personnel/structural risk |

| Certification Standard | General industrial | ISO 13849-1, IEC 62061 |

| Redundancy Requirement | Optional | Mandatory |

For safety functions to work properly, they need response times below 500 milliseconds so they can stop movement before any rope slack gets lost. Operational switches on the other hand can handle longer delays without causing problems. A common mistake happens when people install regular switches where load limiting is needed, which goes against the rules set out in CMAA 74 safety standards. Before installation, it's really important to cross check what type of switches are being used versus what was determined during the official risk assessment for that particular crane. This helps maintain proper safety compliance and keeps workers safe from potential hazards.

Regulatory Compliance: When Crane Limit Switch Deployment Is Mandatory

ASME B30.16–2023 requirements for redundant upper limit switches

The ASME B30.16-2023 standard actually requires these redundant upper limit switches on hoists now, not just because it's considered good practice but because it's written into the codebook. The dual system needs to stop crane movement right before anything goes wrong with over travel. Think about this scenario: when the main switch breaks down mid lift, the backup has got to kick in fast to stop any rope from going slack. These safety measures tackle problems we've seen time and again in accident reports across industries. Look at OSHA data from last year showing single point failures responsible for around 37% of all crane related structural collapses. Getting this right means setting those switches properly, somewhere close to 10% below the top lift position, and checking them every month to make sure they work. Companies that skip these steps face serious money penalties from OSHA running into hundreds of thousands of dollars, plus their insurance might not cover damages if something does go wrong.

CMAA 70/74 alignment for travel and rotation range limitation

The CMAA has set strict rules about where cranes can move and turn through specs 70 and 74. According to these guidelines, limit switches need to be installed at three main points where movement happens: along the bridge, on the trolley itself, and during boom rotations. When any piece of equipment gets close to 95% of what it's designed to handle, these switches kick in automatically to shut off power before anything bad happens like running into walls or other machines nearby. One important thing to remember though? The CMAA doesn't allow people to use these limit switches as regular controls. That mistake actually causes around half of all warehouse accidents that could have been avoided according to National Safety Council data from last year. For proper setup, workers need to write down exact torque numbers for those stopping points and run annual load tests using weights that meet certification standards. Warehouses dealing with dangerous substances will need even more frequent checks every three months instead of once a year as part of these safety requirements.

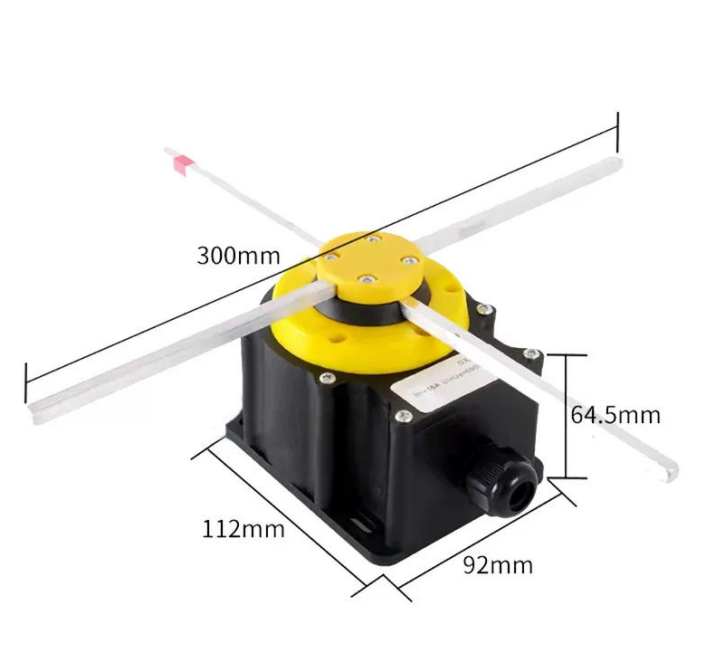

Selecting the Right Crane Limit Switch for Your Application

Picking the right crane limit switch requires looking at several factors including load capacity, how well it stands up to environmental conditions, and whether it works with existing systems. For places where dust and moisture are problems, like construction sites outdoors or near water, go for switches rated IP67 or better. Check the electrical specs too most standard cranes need around 20 to 40 amps to avoid issues when power spikes happen. Make sure whatever gets installed plays nicely with the programmable logic controllers and variable frequency drives already in place. Safety first means sticking to ASME B30.16-2023 standards for critical operations. And don't forget about maintenance access good design here saves headaches later when something breaks down unexpectedly. When all these pieces fit together properly based on what actually happens day to day at the worksite, equipment lasts longer and breakdowns become much less frequent.