Understanding the Role of Crane Limit Switch in Safety and Control

Applications of Crane Limit Switches in Cranes and Hoists

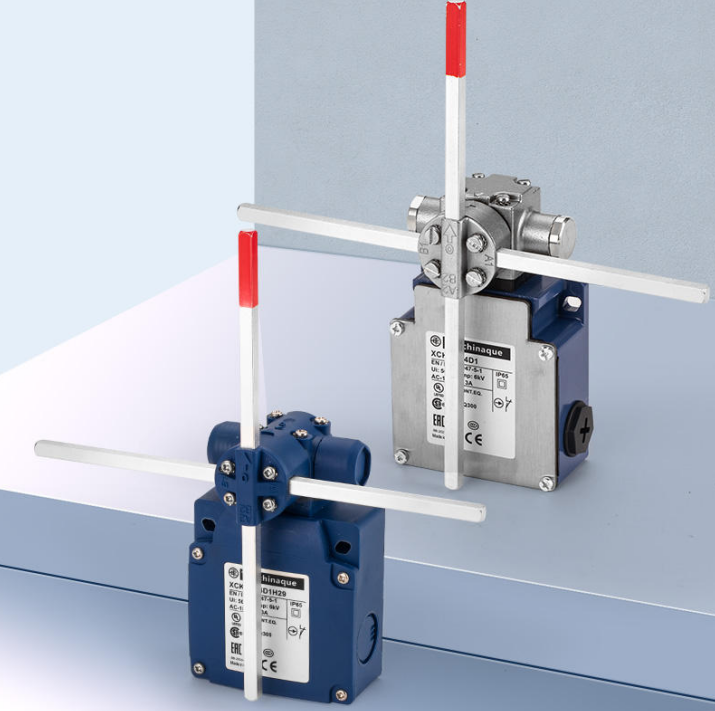

Limit switches on cranes play a vital role in keeping operations safe and controlled across various lifting equipment like overhead cranes, gantry systems, and material hoists. These devices track where parts move mechanically so things stop exactly where they should at specific heights or travel distances. For example, on bridge cranes, the switches stop trolleys before they run off the end of rails. With wire rope hoists, they shut down the motor as soon as the hook gets close to its highest possible position. This stops the load from going too far up and protects the cables from getting damaged during operation.

Role in Safety Interlocks and Emergency Stops

Limit switches on cranes are essential for triggering emergency shutdowns when something goes wrong during operation. These switches work alongside safety interlocks to shut off power almost instantly whenever there's an overload situation, blockage, or mechanical problem. Most electric traveling cranes must have them installed according to OSHA rules and industry standards like CMAA 70/74. Without proper limits in place, cranes can travel too far, leading to dangerous electrical contacts. Industry reports show these incidents happen hundreds of times each year across the United States alone.

Positioning and End-of-Travel Detection for Operational Precision

For applications that demand pinpoint accuracy, most systems need to stay within about 2 mm of their target position. Rotary limit switches work great when monitoring things that spin around, think about those big rotating parts on portal cranes for instance. Linear versions tend to perform better in straightforward movements, which is why they're commonly used in automated stacking operations where movement needs to be strictly controlled along a single axis. The dual stage detection system gives operators a heads up when reaching 95% of the travel distance, then triggers a full stop at the 100% mark. This two step approach helps protect the machinery from sudden impacts and extends how long these systems can operate before needing maintenance or replacement.

Integration with Control Circuits for Automatic Shutdown and Feedback

Limit switches send position information to PLCs in real time, which makes closed loop control possible. When motors get close to their limits, this setup lets them slow down gradually instead of stopping suddenly, which really helps cut down on wear and tear over time. Most systems use either normally open or normally closed contacts for signaling. This redundancy is super important because it keeps things running safely even when something goes wrong. We've seen cases where contacts weld together or corrode over years of operation, but having backup paths means the system still works as intended without complete failure.

Evaluating Environmental Conditions for Reliable Crane Limit Switch Performance

Impact of temperature, humidity, dust, and vibration on switch operation

Limit switches on cranes operating in tough industrial settings such as steel production facilities and port operations must withstand brutal environmental challenges. Temperatures can swing dramatically between -40 degrees Celsius and 85 degrees Celsius, causing plastic parts to break down at about 2.7 times the rate seen in their metal counterparts. When humidity levels climb past 80% relative humidity, corrosion becomes a serious problem for switches without proper sealing. Foundry workers know this all too well since the fine silica dust commonly present there causes roughly one third of regular actuators to jam each year. And then there's the issue of vibration. Switches subjected to shocks greater than 15G experience accelerated wear, which is why many modern installations now specify anti-shock models to maintain consistent operation despite constant movement and impact forces.

Ingress protection (IP) ratings and sealing against industrial contaminants

Switches rated IP65 block 99% of particulate ingress in dusty environments like cement plants, resulting in 58% fewer failures compared to IP54 models. Dual-layer silicone seals maintain integrity under repeated 200°C thermal cycles in aluminum smelters, while hydrophobic coatings prevent moisture-induced short circuits in harbor gantry cranes exposed to salt spray.

Mechanical durability under continuous shock and vibration stress

Premium limit switches withstand shock loads up to 50G during scrap handling operations, with tungsten carbide rollers enduring over 10 million cycles in mining applications. Vibration-dampening mounting systems reduce contact bounce by 89% in ISO 10816-compliant designs, ensuring signal reliability in rail-mounted ladle cranes used in continuous steel production.

Metal vs. polymer housings: Performance in extreme industrial environments

| Material | Temp Range | Impact Resistance | Corrosion Risk |

|---|---|---|---|

| Stainless Steel | -55°C to 150°C | 75 J | Low |

| Glass-Filled Nylon | -30°C to 110°C | 25 J | Moderate |

Stainless steel housings are preferred in chemical plants due to resistance to acidic fumes, while glass-filled nylon reduces weight in bridge crane counterweights by 32% without compromising IP67 sealing performance.

Matching Electrical and Load Requirements with Crane Limit Switch Specifications

Voltage, Current, and Power Load Capacity Considerations

When choosing a crane limit switch, getting the right match for electrical load is essential. Most industrial quality switches handle between 20 to 40 amps continuously, which works well for standard crane motors. Going too small can lead to problems like contact welding when there are sudden power spikes, whereas going too big just adds extra weight and spends money unnecessarily. Take a typical 10 ton overhead crane for instance. The hoist system usually needs something around 30 amps minimum to deal properly with those big power surges that happen especially when stopping suddenly in emergencies.

Electrical Ratings and Switching Capability Under Continuous Duty

For continuous duty operations, we need durable contact materials like silver-nickel alloys because they cut down on electrical resistance and prevent excessive heat generation. Research indicates that switches capable of at least 100,000 mechanical cycles result in roughly 89 percent fewer unexpected breakdowns when used in those massive steel mill cranes versus regular models. Managing heat becomes really important in places where things get super hot, especially around molten metal handling areas where temperatures regularly go past 60 degrees Celsius. The extreme conditions make proper cooling solutions absolutely necessary to keep equipment running smoothly without constant failures.

Arc Suppression Techniques and Contact Material for High-Current Applications

When it comes to arc suppression, techniques like arc chutes and magnetic blowouts play a major role in stopping plasma from forming when contacts separate. Plasma formation is actually responsible for about a quarter of all switch failures according to industry data. The newer generation of switches now incorporates contacts made with silver impregnated tungsten instead of traditional copper options. These advanced materials can handle roughly tenfold more arc interruptions before failing compared to their copper counterparts. This means much longer service life for the equipment. For applications such as port cranes operating near coastal areas where saltwater corrosion is constant concern, this extended durability makes all the difference in maintenance costs and operational reliability over time.

Redundant Switching and Dual-Contact Configurations for Fail-Safe Reliability

When dealing with dangerous stuff like nuclear fuel handling, engineers rely on these special dual-contact switches with built-in monitoring circuits. The stats are pretty impressive too – we're talking about failure rates under 0.001 incidents for every 10,000 operating hours. Why does this matter? Well, if contact welding happens in one part of the system, the backup circuits kick in to maintain those critical safety shutdown functions. And there's something new coming along too. These emerging three-position switches give operators intermediate feedback signals that actually help with predictive maintenance. Mining companies using them report cutting down on inspection work by around 40%, which saves both time and money in an industry where downtime costs big bucks.

Selecting the Right Actuation Type: Linear vs. Rotary for Crane Applications

Linear vs. Rotary Actuation: Matching Movement Type to Crane Mechanics

When picking between linear and rotary actuators for cranes, motion type is what matters most. Linear ones work great when we need that straight line movement precision. They're commonly used on bridge cranes for things like trolley movement across the span or controlling how high the hoist goes. Getting those measurements right down to the millimeter helps avoid going past safe limits. For rotating parts though, rotary actuators are the way to go. Think about those big portal cranes that turn around, or the mechanisms that rotate electrical busbars. According to some recent research from ITG Motors back in 2023, linear actuators actually cut positioning mistakes at bridge crane end stops by about 40 percent when compared with their rotary counterparts. That kind of improvement makes a real difference in day to day operations.

Actuator Design Compatibility With Lifting and Travel Mechanisms

Key selection criteria include:

- Stroke length: Linear actuators with ¥500 mm travel suit long-span gantry cranes

- Torque capacity: Rotary actuators with ¥120 N·m torque resist stalling in slewing applications

- Mounting constraints: Compact rotary designs fit space-limited jib cranes

Dual-sealed actuators maintain contact integrity across 100,000+ cycles under the 5–15 Hz vibration typical in industrial crane operations.

Precision Positioning and Overtravel Prevention in Bridge and Busbar Cranes

When moving ladles automatically, today's bridge cranes need positioning accuracy down to around 2 mm. This kind of precision is possible using roller arm limit switches equipped with those special tapered cam designs. For busbar cranes though, compliance with ISO 12488-1 standards means installing rotary actuators that can detect angles as small as half a degree. These help keep collector shoes aligned properly during operation. Steel mills have found something interesting too about condition monitored linear actuators for their casting cranes. With predictive wear analysis built in, these systems actually cut down on maintenance downtime by roughly 70%. That's a big deal when production schedules are tight and every minute counts.

Future-Ready Crane Limit Switches: Smart Systems and Industry Trends

Smart Limit Switches with Condition Monitoring Capabilities

Modern limit switches come equipped with built-in sensors that keep track of things like contact wear, how aligned the actuators are, and changes in temperature. When these smart switches notice something's off, they send warnings to maintenance crews so problems get fixed before they cause major issues. Some studies suggest this proactive approach cuts down on unexpected equipment shutdowns by around 40-50% compared to older models without such monitoring capabilities. Take vibration sensors for example. These little gadgets installed on bridge cranes can actually spot tiny shifts in rail alignment long before anyone would normally notice anything wrong, sometimes catching potential failures several weeks in advance.

IoT-Enabled Devices and Predictive Maintenance Integration

Connecting limit switches to IoT platforms enables real-time fleet-wide monitoring. Facilities using IoT-enabled predictive analytics have reported a 63% reduction in crane-related incidents through early fault detection. By analyzing historical switch cycle data, these systems forecast component lifespans and automatically schedule replacements during planned maintenance windows.

Case Study: Preventing Bridge Crane Derailment Through Advanced Limit Switching

After switching out their old equipment for dual channel limit switches that can measure down to the millimeter, one particular steel manufacturing plant saw no more derailments happening on their massive 50 ton bridge cranes. Since installing these new systems, instances where the trolleys would accidentally go past their limits fell dramatically - about 89% fewer problems overall. Maintenance expenses also went way down, saving roughly eighteen thousand dollars each year just on repairs. What makes this work so well? The new setup includes redundant optical encoders that constantly send position updates not only to the crane control system but also directly to the main safety monitoring screen, giving operators much better real time awareness of what's going on throughout the facility.

Safety Trends and Reliability Enhancements in Modern Industrial Systems

Three key advancements are shaping the future of crane safety:

- Dual independent circuits that cross-verify switch states before allowing movement

- Self-testing contacts that confirm electrical integrity during startup

- Impact-resistant enclosures maintaining IP67 sealing under 20G vibration

The global market for smart crane safety components is projected to grow 22% annually through 2035, driven by stricter OSHA compliance and increased automation in large-scale infrastructure projects.

Table of Contents

- Understanding the Role of Crane Limit Switch in Safety and Control

- Evaluating Environmental Conditions for Reliable Crane Limit Switch Performance

- Matching Electrical and Load Requirements with Crane Limit Switch Specifications

- Selecting the Right Actuation Type: Linear vs. Rotary for Crane Applications

- Future-Ready Crane Limit Switches: Smart Systems and Industry Trends