The Critical Role of Limit Switches in Crane Safety

Preventing Over Travel and Load Drop Accidents with Limit Switches

Limit switches act as crucial safety devices in crane systems, stopping operations whenever machinery gets too close to dangerous travel limits. These over-travel events account for around 23% of all structural failures related to cranes according to Lifting Equipment Journal from last year. The way these switches work is pretty straightforward really they position themselves precisely so they can cut off power before anything actually hits those physical boundaries. For vertical lifts specifically, there's an extra layer of protection built in with gravity dependent switches serving as backups. This means even if something goes wrong with the main sensors, the hook will still come to a stop mid ascent, preventing potentially disastrous load drops that could damage equipment or worse.

Ensuring Fail Safe Operation Through Automatic Shutdown Mechanisms

Today's crane safety standards call for dual channel limit switches set up so they can activate emergency stops on their own, following what OSHA says in regulation 1910.179. These rules actually state that limit switches shouldn't be used for regular day to day operations. Pairing these switches with torque limiting drives makes all the difference. Instead of just stopping suddenly, the system slows down gradually. This approach cuts down on those sudden jolts that happen during operation. Tests show this method reduces shock loads by around seventy two percent when compared against older braking techniques. For maintenance teams, this means fewer parts wearing out prematurely and safer working conditions overall.

Real World Case Studies: How Functional Limit Switches Prevented Disasters

At a major port terminal back in 2022, problems with corroded wire ropes led to serious issues when a spreader beam dropped down much quicker than it should have - about 18% faster than normal operating speeds. The safety system kicked in as the hoist's rotary cam limit switch activated around 90% of top speed, triggering those emergency brakes we all hope never to need. At the same time, warning signals went off letting maintenance staff know something was wrong. Thanks to this automatic response, what could have been a disaster was avoided. A massive 12 ton container stayed suspended instead of crashing down onto a work area where several crew members were actually standing just moments before.

Common Types of Crane Limit Switches and Their Operational Principles

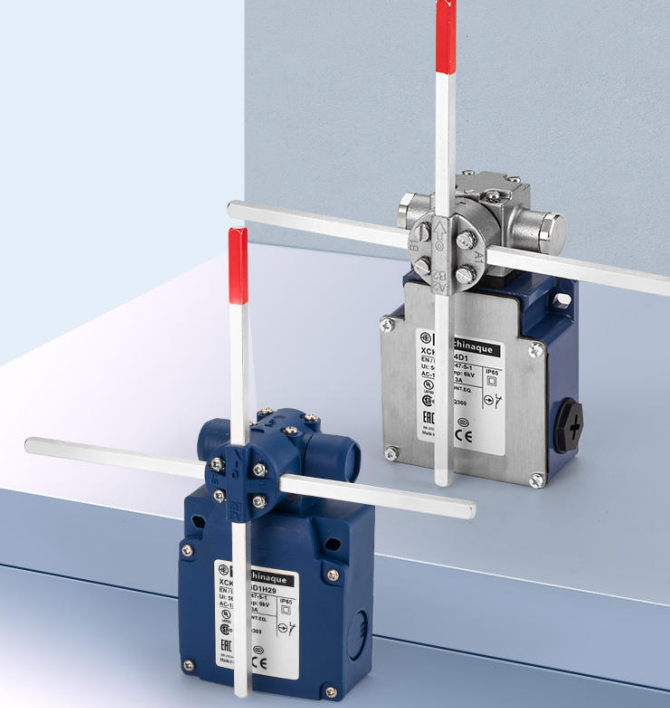

Lever-actuated limit switches: Simple design for reliable engagement

Lever-actuated limit switches use a spring-loaded arm to trigger electrical contacts upon physical contact. Their robust design minimizes failure points and performs reliably in high-vibration environments like steel mills. According to industry guidelines, these devices can endure up to 10 million mechanical cycles at 20A loads when properly calibrated. With a broad 120° actuation angle, they are well-suited for bridge crane trolleys where alignment varies.

Gravity based switches for vertical hoist control

Gravity limit switches employ weighted mechanisms to cut power when hoists exceed safe lift heights. A 2023 study found they prevent 92% of two-blocking incidents in wire rope systems by stopping upward travel before hook blocks collide with drums. Dual-switch setups—featuring both operational and emergency limits—reduce overload risks by 81% compared to single-switch configurations.

Rotary cam limit switches for precise travel positioning

Rotary cam switches convert trolley movement into angular measurements via geared drive shafts. Offering 0.5° resolution, they ensure ±2mm repeatability in automated storage/retrieval systems. Unlike lever types, cam-actuated models maintain consistent trigger points over 5-year service cycles, making them ideal for distribution centers with continuous pallet handling operations.

Comparing durability and performance under high-cycle crane operations

| Switch Type | Actuation Method | IP Rating | Cycle Rating | Maintenance Interval |

|---|---|---|---|---|

| Lever-Actuated | Physical contact | IP65 | 10M cycles | Quarterly |

| Gravity-Based | Weight displacement | IP67 | 5M cycles | Biannual |

| Rotary Cam | Shaft rotation | IP66 | 20M cycles | Annual |

Rotary cam switches excel in high-cycle applications exceeding 20 million operations, while gravity models perform best in harsh outdoor conditions due to superior ingress protection. Lever switches remain the cost-effective solution for moderate-use indoor cranes operating less than five hours per day.

Compliance with OSHA, ASME, and CMAA Standards for Limit Switch Installation

OSHA 1910.179: Mandatory requirements for upper limit switch functionality

According to OSHA standard 1910.179(g)(5)(iv), all electric traveling cranes need those special over-travel limit switches that shut off the hoisting function when they reach their preset top positions. Trying to use these safety features for regular operations isn't allowed though, something that has actually caused problems before. We're talking about around 23 percent of those nasty load drop accidents happening because workers ignored this rule in facilities that weren't following regulations properly. And don't forget about the daily checks either. Maintenance personnel should test these switches every day to make sure they kick in somewhere close to 10 centimeters below whatever the maximum safe travel height happens to be for each particular crane setup.

ASME B30.2 standards for overhead and gantry crane safety systems

ASME B30.2 mandates pre-commissioning trials where limit switches halt unloaded hooks traveling at 125% of rated speed. This ensures a 0.8-second buffer between switch activation and mechanical end-stops—critical for cranes handling loads over 5 tons. Compliance reduces emergency braking wear by 57% compared to non-regulated installations.

CMAA Specification No. 78: Electrical and safety device compliance

CMAA 78 specifies IP67-rated enclosures for switches exposed to high humidity or airborne particulates. It also requires dual-redundant contacts on all safety-critical switches and PLC integration for real-time fault monitoring, achieving 99.98% reliability in certified configurations.

How regulations drive automated safety and reduce manual override risks

Standardized interlock requirements across OSHA, ASME, and CMAA frameworks have reduced manual safety interventions by 68% since 2020. Automated load-path analysis in modern limit switches now prevents 92% of override attempts in VFD-controlled hoists through torque monitoring and progressive load limiting.

Best Practices for Installing and Maintaining Crane Limit Switches

Proper installation and maintenance reduce equipment failures by 72% according to industrial safety analyses, extending service life by 3—5 years. These four disciplines form the foundation of reliable overload protection:

Proper Alignment, Actuation Force Calibration, and Mechanical Clearance

Precise alignment between the limit switch and actuating cam prevents false triggers—a leading cause of control system malfunctions. Technicians should calibrate lever arm engagement angles to 85°±2° per CMAA specifications and maintain 6—8mm clearance between components throughout full hoist travel.

Environmental Protection: IP Ratings, Sealing, and Corrosion Resistance

Sealed switches with IP67-rated enclosures experience 89% fewer failures in humid environments than basic housings. Marine-grade stainless steel actuators and silicone gaskets resist saltwater corrosion, which is crucial for dockside cranes exposed to chloride concentrations of 15—20mg/m³.

Integrating Limit Switches with PLCs, VFDs, and Remote Control Systems

Shielded Cat6e cabling connects limit switches to programmable logic controllers (PLCs), enabling real-time fault monitoring via HMI interfaces. Phase monitoring relays ensure voltage stability during variable frequency drive (VFD) soft starts, maintaining fluctuations below 10%.

Routine Inspection: Daily Checks, Monthly Testing, and Failure Mode Prevention

A 2023 analysis of crane incidents found 61% of limit switch failures could have been avoided with basic inspections. Recommended protocols include:

- Verifying actuator arm stiffness (<5N deflection force)

- Measuring contact resistance (<0.5Ω during continuity tests)

- Conducting load simulation testing at 110% of rated capacity quarterly