Understanding Phase Sequence Relays and Their Working Principle

Definition and Basic Concept of Phase Sequence Relays

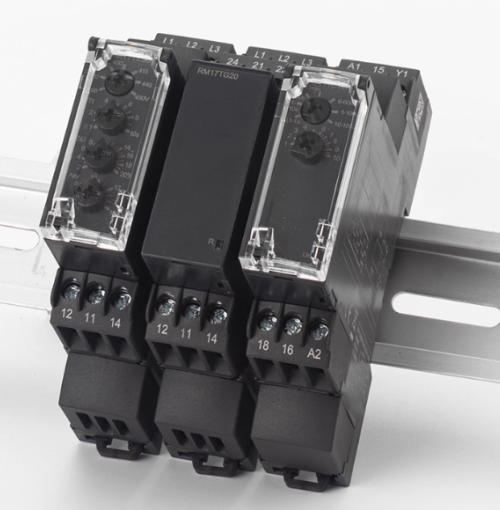

Phase sequence relays serve as critical protection gear for three phase electrical setups. These devices make sure that the voltage phases (L1, L2, L3) come in the right order so equipment doesn't get damaged. Without them, motors and various loads can only run properly if the phase sequence matches what manufacturers specify. The newer models on the market today spot phase problems really fast - about 100 milliseconds actually - which stops headaches like motors spinning backwards or compressors blowing out in HVAC systems. This quick response time saves a lot of money in repairs down the road.

Working Principle in Three-Phase Power Systems

Phase sequence relays work by checking those voltage phase angles with microprocessor logic, making sure there's that standard 120 degree gap needed for proper three phase operation. Take a look at what happens when a 480 volt motor starter gets hooked up to one of these relays. If something goes wrong and the magnetic field starts spinning the wrong way around instead of clockwise, the relay cuts off power fast. This quick reaction stops all sorts of mechanical problems caused by backward torque. Some research from last year actually points out that this kind of protection might be responsible for preventing about a quarter of early motor failures in industrial settings.

Protecting Motors from Phase Reversal and Mechanical Damage

Consequences of Incorrect Phase Sequence on Motor Operation

When the phases get mixed up, three phase motors start spinning backwards instead of forward, which puts a real beating on the mechanical parts. The bearings, those connecting pieces called couplings, and all sorts of drive components take about three times the normal amount of strain when this happens according to Macromatic research from last year. And it gets worse too because the wrong direction creates heat problems inside the motor windings. This overheating is actually responsible for nearly 4 out of every 10 early motor failures across factories and plants nationwide. Fixing these issues costs companies around eight thousand five hundred dollars each time they happen as reported by the Ponemon Institute study back in 2023.

Preventing Reverse Rotation and Associated Mechanical Stress

Modern phase sequence relays continuously monitor voltage phase angles. If deviations exceed ±10° from the ideal 120° spacing, the relay disables the motor starter within 2–3 cycles. This intervention has become standard in industrial facilities, reducing phase-related motor failures by 92% in documented implementations, as noted in the TankTemp Technical Report.

Case Study: Motor Failure Due to Undetected Phase Reversal

At a food processing plant, a maintenance error caused phase reversal in a 150HP compressor motor. The undetected reverse rotation destroyed thrust bearings within 47 minutes, contaminating 8,000 gallons of product and resulting in $220,000 in losses. Post-incident analysis confirmed that a $450 phase sequence relay could have prevented 98% of the damage.

Detecting Phase Loss and Maintaining System Stability

Three phase electrical systems need balanced power to work properly, and phase sequence relays are pretty important for spotting when one phase goes missing. These relays check voltages on each phase line and can catch even minor imbalances around 15%, which usually means something's wrong with connections or maybe a conductor has failed according to the Electrical Safety Foundation report from last year. When motors run on just two phases instead of three, they lose about 40% efficiency and their windings heat up roughly three times faster than normal. Industrial automation folks have seen this happen enough times to know it's not just theory but actual equipment damage waiting to happen if left unchecked.

Relays respond within 100 milliseconds to phase loss, averting:

- Bearing failures due to unbalanced magnetic forces

- Insulation breakdown from overheating

- Damage to downstream equipment

| Phase Loss Impact | Protective Response |

|---|---|

| 22% voltage rise in active phases | Immediate circuit isolation |

| 50% torque reduction in motors | Motor starter disengagement |

| 85% increase in vibration | Automated alarm activation |

Advanced models interface with PLCs to issue predictive alerts when recurring imbalances suggest deteriorating connections. Facilities using such integrated systems report 72% fewer unplanned motor replacements annually, according to industry maintenance reports.

Industrial Applications and Integration with Control Systems

Use of phase sequence relays in motors, pumps, HVAC, and elevators

Phase sequence relays are essential components in protecting vital equipment throughout various industries. When installed on motors and pumps, these devices stop dangerous reverse rotations that can cause serious damage over time such as excessive bearing wear and eventual shaft misalignment problems. For HVAC installations, maintaining correct compressor rotation direction is absolutely crucial since getting this wrong might lead to refrigerant flowing backwards through the system or even frozen coils during operation. Elevator technicians know this well too because their control panels incorporate phase sequence protection to keep those massive hoisting mechanisms running safely while also preventing door actuator failures that could trap passengers between floors. According to recent data from an industrial safety study published last year, nearly one out of every five unexpected shutdowns in fluid handling operations actually stems from issues related to improper phase sequencing.

Integration with motor starters and industrial control circuits

Phase sequence relays hook up to motor starters using those auxiliary contacts we all know about, which kicks in an automatic shutdown when there's a phase reversal or total loss situation. These relays talk to PLCs through their digital input ports, making them a key component in any decent protection strategy setup. Most industrial facilities will tell you that when these systems are properly integrated into control panels, they allow for instant fault recording and work seamlessly with SCADA systems. This means plant managers can monitor everything from one central location instead of running around chasing down issues manually.

Growing adoption in smart manufacturing and Industry 4.0 environments

The rise of Industry 4.0 has really ramped up interest in smart relays that come with communication protocols such as Modbus TCP/IP and PROFINET. These gadgets send out phase information to industrial internet of things platforms which helps predict problems before they happen by spotting imbalances early on. According to some recent research from last year's automation sector report, there was about a 40 percent jump compared to previous years in how many companies adopted cloud linked phase monitoring setups. This trend makes sense when looking at what these systems can do for saving energy costs and extending the life span of motors across different facilities. Most manufacturers today are going for relays that have been certified for cybersecurity features simply because meeting those smart grid compatibility requirements has become almost mandatory in this connected world we live in now.

Improving Safety, Efficiency, and Future-Ready Protection

Key Benefits: Electrical Safety, Operational Efficiency, and Equipment Protection

According to the Electrical Safety Foundation from 2023 research, phase sequence relays cut down on equipment failures around 42 percent in those three phase systems because they catch problems like reversed phases or lost power right away. These devices stop motors from burning out, protect against voltage issues that can cause damage, and help avoid dangerous fires too. Plus they keep operations running smoothly since unexpected shutdowns become much less common. The circuitry inside these relays works super fast, finding faults within just 50 milliseconds. That's actually about 25 times quicker than what someone could do manually. So not only does this technology save money on repairs, it also keeps workers safe when things go wrong with electrical systems.

Balancing Reliance on Relays With Preventive Maintenance Practices

Relays do provide immediate protection, but many experienced technicians actually suggest pairing them with regular checks like quarterly impedance tests and infrared scans too. The reason? These additional methods catch problems that develop slowly over time, stuff like worn insulation or contacts that start to erode gradually something standard relays just miss entirely. A recent look at industrial maintenance practices from last year showed pretty impressive results for companies that combined their relay systems with these proactive approaches. Motors lasted almost 70% longer on average when facilities used this dual approach rather than sticking strictly to relay-based protection alone.

Smart Phase Sequence Relays and IoT-Enabled Predictive Protection Trends

The latest generation of relays now comes with IoT capabilities that let engineers monitor grid health from afar. These devices include various sensors to keep tabs on things like harmonic distortion levels and temperature changes across the system. According to several major manufacturers in the field, there's been about a third fewer problems related to phases since around 2022 when they started using smart algorithms that can spot potential issues anywhere between 8 to maybe 12 hours ahead of time. By connecting relay information directly into predictive maintenance software, these modern systems help companies meet those Industry 4.0 safety requirements while allowing technicians to fix problems right during planned maintenance windows rather than dealing with unexpected breakdowns.