Understanding Crane Limit Switch Functionality and Types

How Travel Limit Switches Prevent Two-Blocking Accidents

When the hook assembly hits the boom tip on a crane, we call this situation two-blocking. It's pretty dangerous stuff that can wreck equipment and put operators at real risk. OSHA reports plenty of crane accidents every year from these kinds of incidents, which shows why good prevention methods matter so much. Travel limit switches play a big role here. These devices cut power to the crane as soon as it gets close to reaching its maximum travel range. This stops the crane arm from going past where it should, avoiding those nasty collisions nobody wants. Regular checkups and tests keep these switches working right. Maintenance crews know they need to test them frequently because faulty switches just invite trouble. Keeping everything properly maintained isn't optional if companies want their cranes running safely day after day.

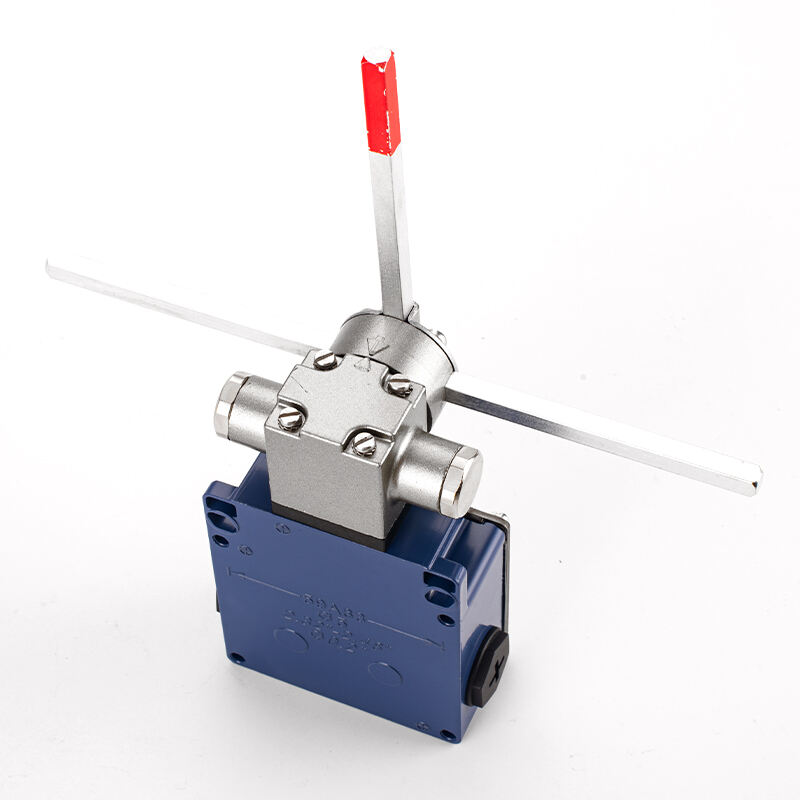

Micro Limit Switch vs Plunger Limit Switch: Key Differences

In crane systems, micro limit switches and plunger limit switches play different but important roles, each designed for particular situations. Micro switches are small units that fit into tight spaces because they're so compact and activate with high precision. These are commonly found in areas where there isn't much room and exact movement control matters a lot. Plunger limit switches take a different approach altogether. They're built for tougher jobs, featuring a mechanical plunger mechanism that detects when parts of the crane reach certain positions during operation. From what many maintenance technicians observe, micro switches work best when fine adjustments are needed, but plunger switches tend to last longer and are easier to install on larger equipment. The choice really depends on the job at hand. Micro switches get chosen for their responsiveness and small size, while plunger switches remain popular in applications where reliable contact points are crucial despite rough handling conditions.

Role of Limit Sensor Switches in Overhead Crane Systems

Limit sensor switches play a key role in making overhead cranes safer and more functional. When installed on a crane system, these devices keep track of where the crane moves around. If the crane gets too close to its set boundaries, the switch stops everything from moving further, which helps avoid dangerous overruns. Most modern cranes have these sensors built right into their control systems. They're especially important in places like construction sites and factories where getting things positioned exactly right matters a lot for production quality. Companies like Honeywell and Telemecanique make some of the best models available today. Their products stand out because they detect limits accurately and give consistent feedback to operators. Adding these switches to an overhead crane setup really boosts overall safety levels. Operators get peace of mind knowing their equipment won't go beyond safe operating parameters, protecting both workers and valuable machinery at the same time.

Critical Standards: ASME B30.2 and CMAA 70 Specifications

Getting familiar with what ASME B30.2 and CMAA 70 require is essential if we want those limit switches on cranes to work properly and keep everyone safe. The ASME B30.2 standard deals mainly with overhead and gantry cranes, laying out all the mechanical requirements needed for them to operate safely, especially when it comes to those critical limit switches. Meanwhile, CMAA 70 goes into great detail about electric overhead traveling cranes, making clear how important strict safety measures really are in practice. According to both sets of guidelines, every crane should have dependable limit switches installed so they can stop moving automatically at certain points. This helps prevent accidents from happening and protects expensive equipment from getting damaged. These aren't just recommendations either; following these standards is actually required by law since they're considered the gold standard across the industry for keeping operations both safe and efficient according to most regulatory agencies.

Mandatory Over Travel Protection in 1910.179 Regulations

OSHA Regulation 1910.179 makes it clear that cranes need over-travel protection devices as part of their safety setup. The rule doesn't just want these devices installed either they must stay properly maintained so the crane stops moving once it reaches its maximum travel limit. Failing to follow this can lead to serious problems both legally and in terms of worker safety. Companies might face hefty fines from regulators and workers could get hurt if something goes wrong. Looking at actual cases helps put this into perspective. A manufacturing plant reported fewer near misses after implementing a thorough compliance check program for their overhead cranes. This shows why sticking to these safety standards matters so much in day to day operations where heavy machinery is involved.

Proper Positioning of Microswitch Limit Devices

Getting the placement right for those microswitch limit devices makes all the difference when it comes to how well cranes work and keeping everyone safe around them. Wanting top performance means looking at several things first: what kind of crane we're dealing with, where it operates day to day, and just how much weight it needs to handle regularly. The actual setup of the crane itself plays a big role too, along with whatever gets lifted (some stuff might be bulkier than others) plus weather issues like dirt buildup or water getting into sensitive parts. Most folks who know their stuff suggest putting these switches somewhere mechanics can get to them without climbing mountains but still shielded enough so they don't get knocked around during normal operations. We see plenty of problems happen because someone installed them crookedly or forgot about protecting against grime and humidity. One factory had to replace half their limit switches after six months simply because they were mounted directly under a leaky roof!

Pre-Shift Functionality Checks and Load Testing

Conducting pre-shift functionality checks is vital for guaranteeing that all safety devices, including limit switches, are functioning correctly. This ensures that cranes operate without unexpected issues that might lead to safety hazards. A checklist of comprehensive tests before each shift can include:

- Visual inspection of limit switches for physical damage.

- Testing the response of each switch in different operational scenarios.

- Verifying electrical connections and outputs.

- Ensuring indicator lights function correctly.

The load testing process further underscores the importance of validating limit switches' effectiveness. By subjecting the crane to maximum operational loads, one can verify that switches accurately prevent over-travel or overloading, thereby reinforcing overall safety.

Calibration Procedures for Limit Switch Microswitches

Calibration procedures for limit switch microswitches are imperative for ensuring their precision and reliability. A systematic approach to calibration involves several steps:

- Using specific calibration tools recommended by manufacturers to adjust switch positioning.

- Implementing techniques such as simulating operational loads to test switch responsiveness.

- Following manufacturer guidelines for calibration cycles tailored to specific crane environments.

Regular calibration maintains the microswitches' accuracy, aligning operational safety standards with industry regulations. Through consistent checks and recalibration, cranes can operate safely, minimizing risks associated with faulty limit switches.

Identifying Bent Safety Latches and Sensor Malfunctions

Spotting problems before they happen matters a lot in crane operations, especially when it comes to things like bent safety latches and faulty sensors. When those metal clips get bent out of shape, they just won't hold everything together right, which puts everyone around the crane at risk. And if the sensors start giving wrong readings about where the crane actually is, operators might make mistakes that could be dangerous. Most experienced technicians recommend checking equipment regularly and investing in newer sensor tech to catch these issues early on. Industry guidelines back this up too, since keeping cranes running smoothly isn't just good business sense but also saves lives. Regular maintenance work includes looking over parts during routine checks, swapping out anything that shows wear and tear, and making sure all the digital systems have the latest software updates installed.

Case Study: Swartz Bay Rescue Boat Incident Analysis

Looking at what happened with the Swartz Bay rescue boat gives us a good idea about problems with limit switch systems. Basically, poor maintenance was behind the whole mess, which ended up putting lives at risk during an emergency situation. According to various technical assessments, nobody had done those basic routine checks or calibrated things properly over time. To stop something like this from happening again, there are several steps that need attention. First off, establish better inspection schedules for all equipment. Second, make sure those limit switches get maintained according to manufacturer specs. And third, train personnel so they know exactly what to do when sensors start acting up unexpectedly. Getting serious about these areas will not only make safety devices work better but also reduce the chances of dangerous situations caused by faulty limit switches down the road.

Avoiding Dangerous Workarounds with Limit Bypasses

Skipping limit switches during crane operations is asking for trouble. Many operators get frustrated waiting for the switches to kick in and try to bypass them just to save time on the job. But what happens next? Equipment damage, dropped loads, sometimes even injuries. Safety inspectors routinely find cases where workers ignored those switches, leading to wrecked machinery and repair bills running into thousands. These aren't just extra parts bolted onto cranes they're actually there for a reason. The switches act as the last line of defense against overloading and mechanical failure. For companies wanting both efficiency and safety, there's a better way forward. Some facilities have started installing smart monitoring systems that track crane performance in real time while still respecting all safety limits. This approach keeps things moving without putting anyone at risk.

Implementing Redundant Safety Layers Beyond Basic Compliance

Adding multiple safety layers to crane systems goes way beyond just meeting regulations. Redundant safety features mean having backups for critical components. Think about things like duplicate sensors or those dual action limit switches that kick in if the primary fails. Many operators actually install both plunger type limit switches and micro switches together on their cranes. Real world data shows that when these redundant systems are properly implemented, workplace accidents drop dramatically while productivity stays high. Most experienced crane technicians will tell anyone who asks that going above and beyond basic requirements with these advanced safety layers makes all the difference in preventing costly downtime and keeping workers safe day after day.

Training Requirements for Limit Switch Monitoring Personnel

Training for personnel who work with limit switches is absolutely necessary if we want to maintain proper safety levels around these systems. Good training programs really need to cover important areas like figuring out when sensors start acting up and knowing what the limits actually are during operation. Most workers aren't just going to pick this up on their own they need hands-on experience with different types of switches including both travel limit switches and micro limit switches which function quite differently from each other. The big names in the industry such as ISO and CE have established certain standards that help determine whether training courses meet minimum requirements for competency in safety procedures and actual switch handling. When companies put real money into thorough training sessions for their crane operators, they see tangible results not only improved safety records but also fewer equipment failures and breakdowns during daily operations.

Table of Contents

-

Understanding Crane Limit Switch Functionality and Types

- How Travel Limit Switches Prevent Two-Blocking Accidents

- Micro Limit Switch vs Plunger Limit Switch: Key Differences

- Role of Limit Sensor Switches in Overhead Crane Systems

- Critical Standards: ASME B30.2 and CMAA 70 Specifications

- Mandatory Over Travel Protection in 1910.179 Regulations

- Proper Positioning of Microswitch Limit Devices

- Pre-Shift Functionality Checks and Load Testing

- Calibration Procedures for Limit Switch Microswitches

- Identifying Bent Safety Latches and Sensor Malfunctions

- Case Study: Swartz Bay Rescue Boat Incident Analysis

- Avoiding Dangerous Workarounds with Limit Bypasses

- Implementing Redundant Safety Layers Beyond Basic Compliance

- Training Requirements for Limit Switch Monitoring Personnel