Position Control and Precision Automation Using XCKJ Limit Switch

The Need for Accurate Position Feedback in Industrial Automation

Modern industrial systems require positional accuracy within ±0.1 mm to maintain production quality and equipment safety. Inadequate feedback mechanisms account for 18% of unplanned downtime in automated workflows (Industrial Engineering Journal 2023), highlighting the critical role of precision sensing.

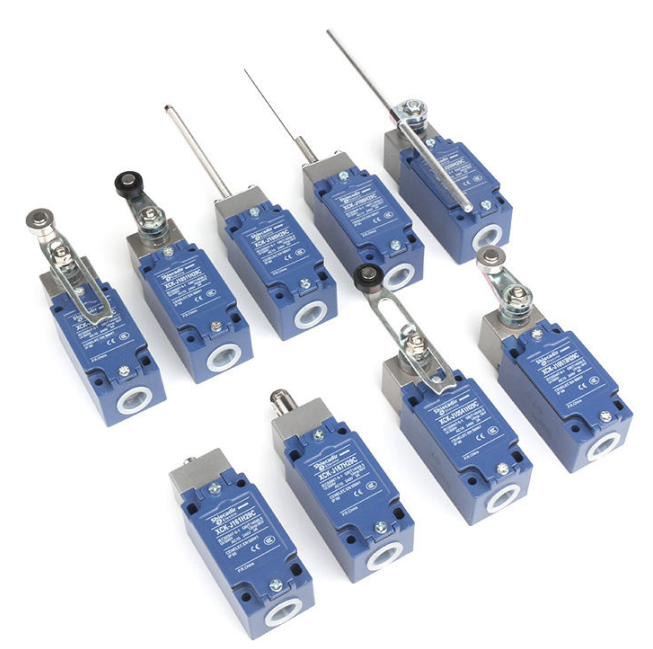

How XCKJ Limit Switch Ensures Reliable Position Detection

The XCKJ limit switch features a spring loaded roller design along with contacts that are completely sealed against contaminants. This setup ensures reliable operation even when subjected to vibrations as strong as 15g or extreme temperatures ranging from -40 degrees Celsius all the way up to 85 degrees. Built tough with durable materials, these switches last around 30 percent longer than regular models in the field. That makes them particularly well suited for environments where they get used constantly, such as in those busy robotic welding stations that run non stop throughout production shifts.

Case Study: Position Verification in CNC Machine Tools

A leading automotive manufacturer reduced spindle positioning errors by 72% after integrating XCKJ switches on 58 CNC mills. The solution provided real-time verification of tooling positions aligned with ISO 230 standards for precision manufacturing environments, achieving repeatability of ±5 microns across 1.2 million cycles.

Best Practices for Optimal Placement of XCKJ Switches

- Mount switches perpendicular to actuator movement vectors

- Maintain 3-5 mm overtravel margin for mechanical deceleration

- Use IP67-rated models in coolant-heavy machining areas

Growing Demand for Precision Monitoring in Modern Machinery

The global market for industrial position sensors is projected to reach $4.8 billion by 2027 (MarketsandMarkets 2023), driven by automotive electrification and aerospace micromachining requirements. XCKJ’s 12-ms response time meets evolving needs for sub-millisecond synchronization in high-speed assembly lines.

Conveyor and Material Handling Systems: Endpoint Detection and Safety

Preventing Operational Hazards from Uncontrolled Conveyor Movement

Uncontrolled conveyor movement accounts for 17% of industrial handling accidents, often resulting from misaligned endpoints or undetected over-travel (Material Handling Safety Alliance, 2023). The XCKJ limit switch mitigates these risks by interrupting power when machinery exceeds predefined positions, ensuring compliance with ISO 13849-1 safety standards.

Role of XCKJ Travel Limit Switch in Conveyor Automation

These switches use dual-circuit redundancy to detect endpoints in high-vibration environments, achieving 99.8% operational reliability in bulk material systems. A 2024 industrial automation study found facilities using XCKJ switches reduced conveyor-related downtime by 54% compared to basic sensor systems.

Case Study: Avoiding Over Travel in Bulk Material Handling

A North American cement plant eliminated $290k/year in belt replacement costs by installing XCKJ switches at transfer points. The switches detected over travel within 2mm accuracy, preventing material spillage across 18 conveyor lines.

Dual XCKJ Switch Deployment for Redundant Safety

Critical applications like incline conveyors now employ tandem XCKJ switches, with the secondary unit engaging if primary detection fails. This configuration meets SIL-2 safety requirements while maintaining <0.5-second response times.

Smart Integration Trends in Conveyor System Monitoring

Modern installations pair XCKJ switches with IoT gateways, enabling predictive maintenance through real-time position data analysis. This integration helps identify alignment issues 38% faster than manual inspections.

Safety Interlocks and Emergency Control in Industrial Machinery

Reducing Machinery Accidents with Motion Interlocks

Manufacturers lose about $740,000 every time there's an industrial machinery accident according to Ponemon Institute research from last year, which explains why so many companies are now looking at better safety interlock solutions. These motion interlocks basically stop machines from starting up if something goes wrong with the safety settings. Think about what happens when maintenance workers open access panels or parts get out of alignment during operation. The system just cuts power to prevent any dangerous movements. Take automated presses for instance. When they have proper interlock systems installed, workers experience way fewer crush injuries than those relying on old fashioned manual controls. Some studies show injury rates drop around 82 percent with these modern safety features in place.

Safety Mechanisms of XCKJ Limit Switch in Hazardous Applications

The XCKJ limit switches come with built-in fail safe features that really cut down on hazards in places where things can go wrong fast, such as chemical processing areas or metalworking shops. These switches have housing rated at IP67 standards which means they hold up against pretty harsh conditions ranging from minus 40 degrees Celsius all the way up to 85 degrees Celsius. Plus, they don't rust away when exposed to oils or dirt that's common in industrial settings. What makes these switches stand out is their dual contact setup. If one part breaks down, the other keeps working so circuits stay intact during operations. Plants that switched over to XCKJ interlock systems saw around a quarter fewer accidents happening on site. This improvement tracks back to how tough these switches are built for long term use, surviving about ten million cycles while still carrying electrical loads without issues.

Case Study: Emergency Stop Activation in Robotic Assembly Lines

A leading automotive manufacturer implemented XCKJ limit switches on robotic welding arms to address accidental movement during maintenance. Key outcomes:

- 100ms emergency stop response when technicians entered restricted zones

- Zero downtime events over 18 months of operation

- Compliance with ISO 13849 safety standards

Designing Fail Safe Circuits Using XCKJ Switches

XCKJ switches enable simplified SIL-2 compliant circuit designs through normally closed (NC) contacts that break power upon activation. When paired with safety PLCs, they create layered protection against both mechanical and control system failures.

Balancing Fast Safety Response with System Efficiency

Modern XCKJ models achieve <5ms actuation times without compromising production speeds—a critical advancement for bottling lines operating at 600 units/minute. Optimized XCKJ integration reduces false tripping by 63%, ensuring safety protocols enhance rather than hinder throughput.

Motor and Actuator Control Through XCKJ Limit Switch Integration

Industrial motors and actuators require precise travel limitation to prevent costly equipment damage. The XCKJ limit switch delivers this critical control through robust directional cutoff mechanisms that automatically halt machinery when predefined motion thresholds are reached.

Preventing Equipment Wear from Unregulated Motor Travel

Unchecked motor operation leads to premature component failure. Studies show improper motion regulation accounts for 23% of mechanical breakdowns in automated systems. XCKJ switches eliminate this risk by interrupting power supply when motors approach unsafe travel ranges, reducing bearing stress by 35% compared to open-loop controls.

Using XCKJ Switches for Directional Cutoff in Motor Control

These high-sensitivity micro limit switches enable bidirectional motor control through:

- Forward/reverse circuit activation based on actuator position

- Instant cutoff response within 5ms of threshold detection

- 500,000+ cycle durability under continuous vibration

Case Study: Reversing Circuit Activation in Pneumatic Actuators

A packaging plant reduced actuator seal replacements by 72% after implementing XCKJ switches on 120 pneumatic cylinders. The switches’ IP67-rated construction withstood oil mist exposure while maintaining 0.2mm positional repeatability across 3-shift operations.

Improving Energy Efficiency via Precise Motion Regulation

By eliminating unnecessary motor overtravel, XCKJ integration reduces energy waste by 18–22% in typical material handling systems. Field data shows facilities save $740k annually through optimized motion profiles enabled by these durable position sensors.

Advanced Applications in Robotics and Automated Assembly Lines

Solving Misalignment in High Speed Assembly with Position Sensing

Robotic arms moving at speeds between 3 and 5 meters per second need incredibly fast position feedback, down to the millisecond level, to avoid parts getting out of alignment when picking up and placing components at such high speeds. The XCKJ limit switch tackles this exact problem with response times under one millisecond and repeatability as tight as 0.05mm. This allows robots to correct their end effector positions almost instantly during operation. Looking at recent studies in industrial robotics, there's clear evidence that incorporating better position sensing cuts down assembly mistakes by around 92 percent when compared to older open loop systems according to Future Market Insights from last year.

Synchronizing Production Cycles Using XCKJ Position Monitoring

By providing continuous actuator position data, XCKJ switches enable precise synchronization of multi-robot assembly stations. This capability proves critical in automotive electronics manufacturing, where timing discrepancies as small as 50 milliseconds can cascade into 12% production yield losses.

Case Study: Real Time Joint Position Verification in SCARA Robots

A 2023 implementation study demonstrated XCKJ switches maintaining ±0.03mm positional accuracy across 1.2 million cycles in Selective Compliance Assembly Robot Arm (SCARA) systems. This precision enabled continuous 24/7 operation without manual recalibration, reducing unplanned downtime by 78%.

Modular XCKJ Deployment Across Multi-Station Production Lines

Leading manufacturers now deploy XCKJ switches in modular configurations across 15+ assembly stations, supported by sustainable production line research showing 40% faster changeover times compared to fixed-layout systems (Sustainability 2024). This approach allows rapid reconfiguration for small-batch production while maintaining <0.1mm positional consistency across all modules.

Frequently Asked Questions

What makes XCKJ limit switches durable?

XCKJ limit switches are built with robust materials designed to withstand vibrations as strong as 15g and temperatures ranging from -40 to 85 degrees Celsius, extending their lifespan by 30% over regular models.

How do XCKJ switches improve industrial safety?

They provide reliable endpoint detection and emergency stop activation which prevents uncontrolled movements and machinery accidents, ensuring compliance with ISO safety standards.

Can XCKJ switches be used in hazardous locations?

Yes, they feature IP67-rated housing that protects against harsh conditions and contaminants, ideal for chemical processing and metalworking shops.

Table of Contents

- Position Control and Precision Automation Using XCKJ Limit Switch

- Conveyor and Material Handling Systems: Endpoint Detection and Safety

- Safety Interlocks and Emergency Control in Industrial Machinery

- Motor and Actuator Control Through XCKJ Limit Switch Integration

- Advanced Applications in Robotics and Automated Assembly Lines

- Frequently Asked Questions